The migration to zero emission will impact more than air quality; attachments like PTOs, for example, that rely on those engines for power.

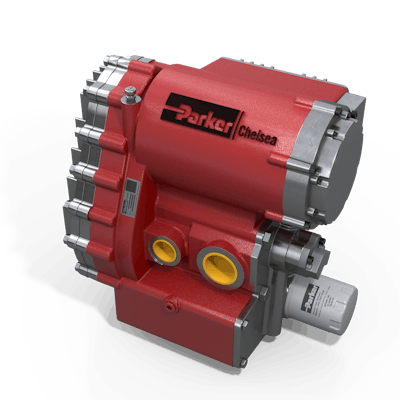

Parker Chelsea Wednesday at Work Truck Week in Indianapolis debuted two integrated electric PTOs that can be installed on BEV and hybrid-electric vehicles. Part of the ePTO Series, both the e910 Series and the e970 Series are designed to maximize run time and optimize efficiency.

Chelsea Products Division Engineering Manager Brian Rang said his team worked alongside chassis OEMs, body builders and customers to understand system requirements, including power, voltage, load, safety interlocks, space and more.

Designed for medium-heavy duty applications, the e970 features 70 kW nominal power and configurable speeds and torque to optimize efficiency. An internal coolant system prevents subcomponents from overheating and can be configured with external coolant for higher power applications. The unit features GVM and GVI. Gear ratios maximize torque and minimize frame size.

Designed for medium-heavy duty applications, the e970 features 70 kW nominal power and configurable speeds and torque to optimize efficiency. An internal coolant system prevents subcomponents from overheating and can be configured with external coolant for higher power applications. The unit features GVM and GVI. Gear ratios maximize torque and minimize frame size.

"The trucking industry will play an integral role in reducing carbon emissions with the development of electric chassis,” said Emily Guerra, Chelsea Products Division marketing manager. “As a key player in the vocational truck market, Parker Chelsea continues to develop innovative products to serve our customers through this transformation of technology, starting with our new ePTO.”

The e910 Series ePTO features a highly efficient Denison Vane Pump that can be configured for multiple flow rates and pressures. The ePTOs feature a Global Vehicle Inverter (GVI) from the Electronic Motion & Controls Division.

Designed for medium-heavy duty applications, the e970 features 70 kW nominal power and configurable speeds and torque to optimize efficiency. An internal coolant system prevents subcomponents from overheating and can be configured with external coolant for higher power applications. The unit features GVM and GVI. Gear ratios maximize torque and minimize frame size.

Designed for light-medium duty applications, the e910 features 10 kW nominal power and configurable speeds and torque to optimize efficiency. Its internal coolant system prevents subcomponents from overheating and eliminates the need for external cooling. It also features a GVM, GVI and Vane Pump and gear ratios to maximize torque and minimize frame size.