Mack Trucks today introduced a new split-shaft functionality for its Mack mDRIVE HD automated manual transmission (AMT), giving customers with high-demand power take off (PTO) needs a fully integrated solution.

The new feature is standard on all Mack mDRIVE HD AMTs. Mack made the announcement this week in Las Vegas at World of Concrete 2018.

“Mack Trucks’ legendary durability was built on the foundation of the fully integrated powertrain we pioneered more than a century ago,” said Tim Wrinkle, Mack construction product manager. “With this new functionality, we’re able to bring the benefits of the mDRIVE transmission to customers whose applications require higher PTO power and torque.”

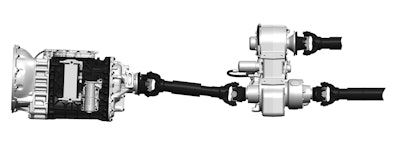

Instead of taking power from an engine- or transmission-mounted PTO, split-shaft PTOs are mounted in the middle of the driveline to receive output directly from the transmission, supplying more torque for auxiliary equipment such as large concrete pumps, vacuum body or high-pressure liquid transfer applications.

While the split-shaft PTO is engaged, power to the axles is disconnected. The split-shaft functionality is standard on all 12-, 13- and 14-speed mDRIVE HD AMTs and can be activated by a Mack dealer. In addition, all GHG2017 F-Series mDRIVE HD AMTs can be reprogrammed with split-shaft functionality with assistance from the Mack Body Builder Support Group. This new functionality also allows transmission start in 7th thru 12th gears and shift to a desired continuous operation gear of 11th or 12th.

Introduced in 2015, the Mack mDRIVE HD is built for hard work. It features reinforced internal components, including stronger gears and synchros to withstand more frequent shifting that is often needed in construction applications. Despite its toughness, the mDRIVE HD is up to 237 pounds lighter than other transmission options, enabling customers to haul even more payload. The mDRIVE HD 13-speed AMT is standard on Mack Granite models.

The mDRIVE HD is fully integrated with Mack’s MP series engines and Mack proprietary drive axles. This integration enables unique transmission software packages, which can be selected based on the customer’s application. An “Enhanced Construction” package provides optimized on/off-road performance and gives the driver full control over any terrain, while an “EZ Shift” package delivers smoother shifts for sensitive payloads like bulk liquids.

Available in direct or overdrive configurations, the 13- and 14-speed Mack mDRIVE HD AMTs offer low reduction creeper gear ratios designed for easier startability on steep grades or when the truck is carrying a heavy load. With this improved startability customers are able to select a faster rear axle ratio, which decreases engine rpm at highway speeds, saving fuel as the truck travels between job sites.

The mDRIVE HD, like all Mack mDRIVE AMTs, is monitored by Mack GuardDog Connect and is serviceable at any of the more than 430 Mack dealers across North America. GuardDog Connect is Mack’s standard telematics solution that provides proactive diagnostics and repair planning. The system monitors fault codes that could potentially shut down a truck or lead to an unplanned visit to the dealer. GuardDog Connect enables quick diagnosis of issues, proactive scheduling for repairs and confirmation that needed parts are in stock and ready to install, all while the truck is still on the job.