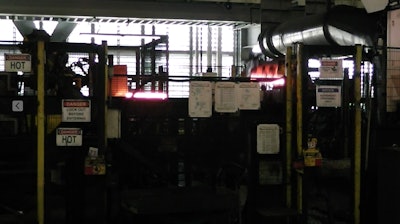

Crankshaft forging is impressive--it takes only seconds to go from red hot steel to a cast crankshaft.

Crankshaft forging is impressive--it takes only seconds to go from red hot steel to a cast crankshaft.

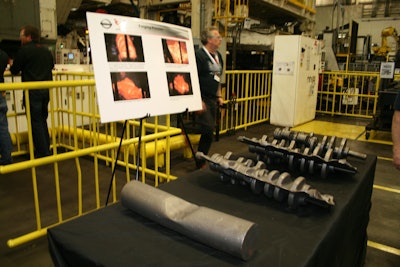

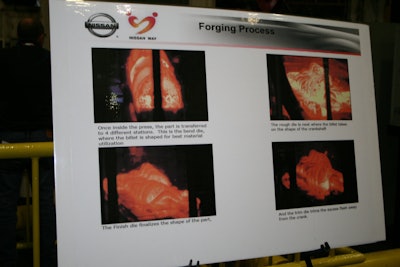

Nissan's crank forging process.

Nissan's crank forging process.

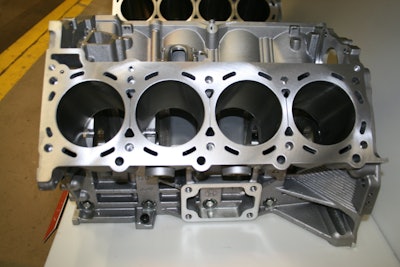

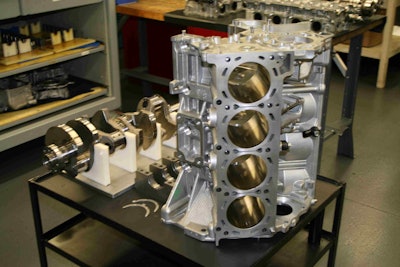

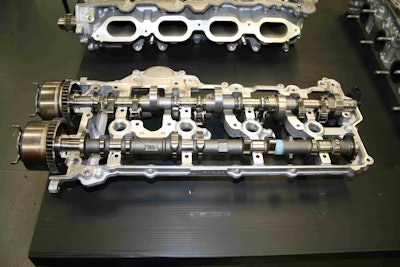

Disassembled 5.6-liter Endurance following 100-hour dyno test.

Disassembled 5.6-liter Endurance following 100-hour dyno test.

Disassembled 5.6-liter Endurance following 100-hour dyno test.

Disassembled 5.6-liter Endurance following 100-hour dyno test.

Disassembled 5.6-liter Endurance following 100-hour dyno test.

Disassembled 5.6-liter Endurance following 100-hour dyno test.

Disassembled 5.6-liter Endurance following 100-hour dyno test.

Disassembled 5.6-liter Endurance following 100-hour dyno test.

The rhythmic pounding during crankshaft forging at Nissan’s Decherd Powertrain Assembly Plant is strangely hypnotic.

In about 12 seconds or less, depending on the size of the crankshaft, imposing machinery transforms red-hot steel into a piston pumping dynamo that is at the heart of various Nissan engines.

Hard Working Trucks and other media had a chance to tour the engine plant in Dechard, Tennessee this week during a ride impression of the 2016 Nissan Titan XD V8 gas model. Ride impressions are embargoed until Monday morning.

Engines at the vast 1,080,000-sq. ft. complex are produced every 19 seconds. During 2015, the plant manufactured 1.18 million engines, making what Nissan reports is the most productive powertrain plant in the nation. About 1,600 employees work there.

Reporters had a chance to see Nissan’s new 5.6-liter Endurance V8 gas engine being produced and closely scrutinized for those who’d rather have that at the heart of the 2016 Titan XD pickup instead of the 5.0-liter Cummins turbo diesel.

One of the most impressive stops for reporters was the dyno test. The new 5.6-liter engine, which will also be available for the 2017 Titan, was being closely monitored while running fast and hard at around 6,000 rpm for 100 hours.

An engine that had already undergone its turn at the dyno was disassembled nearby. Other than a faint carbon ring at the top of each cylinder, the engine looked clean and unscathed.

Over 150 parts are used to assemble the new 5.6-liter Endurance. Performance gains for the 2017 Titan powerplant over last year’s V8 include a jump from 317 to 390 horsepower and an increase in torque from 385 to 401 foot pounds.

Jay Boyte, Nissan’s senior manager of manufacturing engineering at the Dechard plant, explained that variable valve lift in the new 5.6-liter Endurance has led to better acceleration. More on that later in Monday’s HWT ride impression.