Shell Lubricants has been busy expanding its reach in electric and other alt fuel technologies, but as far as heavy-duty trucks, the global energy giant expects diesel to be on the road for a long time to come.

A surge in electric car sales combined with the gradual roll-out of commercial electric trucks and vans driven in part by tough emissions goals and attractive incentives have led Shell to invest further in technologies that support electric power.

This year alone Shell Lubricants acquired California-based electric vehicle charging network Green Lots and battery producer Sonnen in Germany. Green Lots has charging stations in the U.S. and Asia while Sonnen produces proprietary lithium-ion batteries powered by solar energy that offer U.S. and European households back-up and supplemental power.

The acquisitions follow Shell’s charger growth in Europe where Shell subsidiary NewMotion operates more than 40,000 electric charge points for EV charging at home and work in the Netherlands, Germany, France and the UK.

In addition to its battery and charger businesses, Shell remains active in developing new lubricants, coolants and other technologies that support the fast-growing EV industry. EV sales from 2017 to 2018 surged 84 percent in California according to the California Air Resources Board.

“Electrification is an important thing particularly in the automotive sector but increasingly so in the heavy-duty sector as well,” said Bob Mainwaring, Shell’s technology manager for innovation within global commercial technology.

Mainwaring, who talked about electric vehicles earlier this month at a Shell Lubricants press event in Barcelona, Spain, said while electric cars are becoming increasingly popular, the more demanding duty cycles of heavy-duty trucking demand greater battery energy density levels.

“For trucks, it’s very much harder,” Mainwaring said. “The amount of energy they need to get the distances they need—long haul freight, for instance—are very much larger. I think how things stand, battery energy density isn’t high enough to propel trucks far enough without reducing the payload of the truck very substantially.”

Dr. Richard Tucker

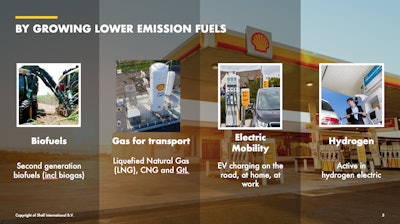

Dr. Richard TuckerDr. Richard Tucker, Shell’s general manager of B2B lubricants and supply chain technology, said in addition to heavy-duty electrification hydrogen has shown promise as an alt fuel for trucks. Shell has already been providing hydrogen to fuel cell cars at locations in the U.S., Canada, Germany, the Netherlands and the U.K.

“I think hydrogen is one of the more promising alternatives for cars in certain places and also for trucking, but it has quite a long way to go,” Tucker said. “I think it will be part of what we call this mosaic of solutions. In some places it will be economically advantaged. It will penetrate to a certain extent. We also think the gas side will penetrate more, but it will still be a major role for diesel engines for a good long period of time.”

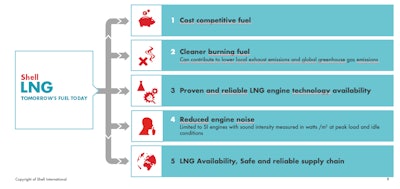

For heavy-duty fleets that want to lower emissions now, both Mainwaring and Tucker suggest turning to Shell’s liquified natural gas.

Opportunities in EV and hybrid markets

Emerging EV and hybrid technologies offers plenty of opportunities for Shell including battery cooling, battery manufacturing and critical lubrication points like transmissions and axles.

EV batteries are typically liquid or air-cooled. In the case of a liquid cooled system, a glycol-based coolant like Shell Rotella Extended Life Coolant flows through tubes that wrap around battery cells. Immersive cooling for EV batteries is also being explored.

“Increasingly, people are looking at taking the battery and radically cooling it by immersing it in a fluid and so we’re working on that technology very hard at the moment because then you could probably achieve fast-charging—that ten minutes or so to charge your car which is a bit of the Holy Grail for these things,” Tucker said.

Electric motors can also be cooled by immersion but as with batteries compatibility with electrical components is key.

“In the stator of many inductive motors, those conductors run parallel to the stator and designs are being set now where you can run lubricant through the stator to cool those conductors directly,” Mainwaring said. “So the heat transfer properties matter because you want to get heat away quickly, but each of those conductors is coated in a varnish to make them electrically isolated. What you don’t want is the lubricant or its additives to eat away at that varnish and make them short out across.”

High-spinning electric motor parts can cause increased aeration which leads to foaming and less protection. Shell’s GTL (Gas to Liquids) oils can help.

“Shell manufactures a gas-to-liquid base oil which is almost paraffinic in nature and a consequence of that is that it takes in very little air and if it has air within it, it sheds it very, very quickly,” Mainwaring explained. “So if you’re in an environment like an electric motor where things are spinning very quickly or a gear train that’s spinning quickly, GTL is very good at not taking air in and as a consequence very good at not producing foam. So you’ve got a really good attribute there that’s natural from the base fluids that we use in our significant premium products.”

“A lithium battery has an anode and a cathode like any battery,” Tucker explained. “It has a separator between them. The separator’s a sort of plastic film that relies on having porosity in it. You achieve that. One of our products is used in the production of that plastic film to get the porosity in there. Right back to the fundamentals of the lithium battery, we’re in there in that sense. We’ve got a lot of different elements where Shell is in the car, so to speak.”

Plug-in hybrids, which qualify for a federal tax credit, can be challenging from a lubrication standpoint given the more active roll that electric motors play. One of the byproducts of combustion is water vapor which enters the engine oil. Normally, engines get hot enough to evaporate the water, but that’s not always the case for a plug-in hybrid.

“In a normal operation, the engine oil gets hot enough to evaporate that away but if it’s a plug-in hybrid running for short periods of time, you might be left with water in the oil which can lead to emulsions and a lower viscosity,” Tucker explained. “The protections of the engine against those things might turn out to be quite complex so that’s another opportunity for us to research. It’s an anxiety that OEMs and oil companies have at the moment that deserves some attention and indeed we’re doing work in that space.”

In addition to playing a roll in the production of separators for lithium batteries, Shell is also supplying EV companies with e-fluids as Tucker calls them. The fast-growing EV sector features several companies that may have little auto experience, Tucker said.

“Picking the winners in this kind of field and knowing who’s going to survive and thrive in this field—I don’t think anybody knows at the moment,” Tucker said. “We’re working with a couple of companies that we’ve never worked with before. For example, in the battery technology space, they’re looking for new things to do new things with batteries to enable fast-charging for example. We would have never spoken with these guys before but the game is changing.”